|

|

|

A. Generals

Wire Rope Pulling Hoist is a kind of small type hand-operated hoister, it's compact in structure, small in size, light in weight, has a longer operating life, less power expenditure and considerably less rope wear.

It is operated in accordance with lever principle by the means of pulling the forward handle or the backward handle manually to make it move to finish three performances such as lifting, pulling and tensioning with less manual force to obtain the load of more tonnage.

It's widely used in construction sites, laying of large pipes, installation and adjustments of machines, loading and unloading heavy and bulky goods, tensioning cables, heaping of forest products, obstacles removing etc.

B. Operating Method

1, Reeve: (Fig. 1) With the rope head downward and pressing the hoister, push the relaxed handle ahead, when hearing the crack sound, plier's mouth has been opened. Then you can reeve the wire rope from the back hole to the hoister. After the rope is out, the rope can be pulled to the length that you need and then push the relaxed handle back to clamp the rope tightly. When the forward handle or the backward handle pulled, the wire rope will automatically go into or come out of the hoister. Thus, the machine is in the normal state and it is ready to be used.

Fig1. Rope reeving and Rope receiving

2, Anchor: Fixed axis is to be used to anchor the rope round the hoister. Connect the wire rope or the hanger with the fixed rope and tie the other end to the load, masts etc. There is a relaxation-proofing tunnel on the fixed axis. When the fixed axis is inserted into the hoister case, it must be turned twice to the second tunnel till it is clamped tightly (Fig. 2).

Fig2. Turn and push the fixed axis twice and let it enter the second tunnel

3, Operate: Hook the load on the hanger

Do as following:

(1) Lift (or pull a load forward), tension: pull the forward handle. (Fig3.: A, B)

Fig3. A Fig3. B

Fig3. A,B: Pull the forward handle to and fro, the black clamping and the white relaxed.

(2) Lower(or pull a load backward): Pull the backward handle. (Fig3.: C, D)

Fig.3 C Fig.3 D

Fig3. C,D: Pull the backward handle to and fro, the black clamping, the white relaxed.

(3) With special attachments (such as fixed and movable pulley blocks and so on), it can be used for unlinear pulling and by means of the attachments, the capacity of the machine may be multiplied.

(4) Stop working: Whenever lifting or lowering the load, it will stop working to make the load stay in any position when the manual handle stops working.

(5) Draw the rope out (Fig. 1): Having finished the work, the pliers mouth will be opened as soon as the relaxing handle is pushed and then the wire rope can be drawn out of the end of the hoister. Clean the dirt on the rope, wind it onto the reel cross in good order to be ready to use next time.

Finally, push back the relaxing handle in order not to let pliers mouth open for long to keep the pretension spring working well later.

C. Caution

1. Please operate the machine according to the rated loading capacity. When it is overloaded, the safety pin will work to cut off automatically. In that case, please replace safety pin before operating it again.

2. Before operating the hoister, you must check all the tightened screw to see if any of them is loosened. If there is any, tighten it. And when pulling one of the handles, make sure whether the hoister works in good order and whether the other handles will move as it does. After the wire rope has been reeved, it can come out or go inside the hoister. The wire rope must be clean and is not twisted, cracked and part-broken, otherwise the hoister will not work properly.

3. Strictly forbidden in operation:

a. Never pull all the handles at the same time.

Don't pull the relaxing handle after the load is being lifted.

b. Never pull the handle violently, otherwise the safety bolt will be damaged. Don't use any self-made safety bolt instead of that provided by our factory if this happens.

c. Never use any pulling lever whose length has been changed by any means. If any, the consequence should be responsible by yourself.

d. Never stand on the load nor work on it (except working in a hanger frame). When any worker works in a hanger frame, its total supporting weight should be reduced to one third rated power of the hoister and the worker in the hanger frame should take measures to protect himself in case some unhappy accident happens.

e. Never use the wire rope chosen by yourself instead of the old one. If it is done or any accident happens, the consequence should be responsible by the users. When the diameter of the working part of the wire rope has been damaged by 10%, a new one provided by our factory should be replaced. Never reeve the rope from the head of the hoister (Fig.4) or the direction of the hook must not be used reversely. If it does so, work can't be done or accident is easy to happen. While working, the anchored object should be strong enough so as to support the load to prevent any accident happening.

Fig.4

f. Keep the machine clean and don't let earth, mud or other dirt pollute the machine. If polluted severely, it must be unassembled to be cleaned. When it is reassembled, never fix the parts by mistake and coat them with lime grease to keep it working properly.

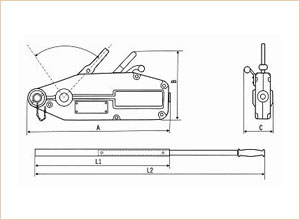

WIRE ROPE HOIST SPECIFICATIONS

|

Model Item |

800 |

1600 |

3200 |

|

|

Rated capacity(kg) |

800 |

1600 |

3200 |

|

|

Rated forward handpower (N) |

341 |

400 |

438 |

|

|

Rated forward travel |

≧52 |

≧55 |

≧28 |

|

|

Rope diameter(mm) |

8.3 |

11 |

16 |

|

|

Wire rope safety factor load capacity |

5 |

5 |

5 |

|

|

Safety factor & static load capacity |

4 |

4 |

4 |

|

|

Max.traveling load (kg) |

1200 |

2400 |

4000 |

|

|

Net weight (kg) |

6.4 |

12 |

23 |

|

|

Max.overall size |

A |

426 |

545 |

660 |

|

B |

238 |

284 |

325 |

|

|

|

C |

64 |

97 |

116 |

|

L1(cm) |

|

80 |

80 |

|

|

L2(cm) |

|

120 |

120 |

|

|

L3(cm) |

80 |

|

|

|